|

The Design module is focused on getting accurate numbers for FF&E costs, prices and taxes, but only uses a percentage-based "estimated" approach for freight since items aren't grouped into orders at this point, and the shipping costs (and suppliers) can change over time. For this reason, estimated shipping is calculated separately from the specification prices and normally added as a lump sum at the bottom of the quote format. (After you create an order for a vendor's items, you have a freight quote field in which to record the freight associated with that order.)

A previous section, Working with Markups, Taxes, Freight and Fees, covered how to incorporate freight quotes into an adjusted percentage for specific specifications as a way to make the freight in an FF&E quote more accurate, but doesn't change the basic way freight is handled on the Design side.

However, if you wish to do an FF&E quote that builds quoted or estimated freight amounts into the sell price seen by the customer, there is a way to do this. It takes advantage of FF&EZ's object-component model to build an object that records all freight quotes with a zero sell price. This gives you the total freight cost for the project (the object's total cost), but doesn't create a separate invoice line for freight. Instead, you calculate the amount of markup to cover the total freight (without or without a freight markup) and use the Pricing Tool to add that to the project's sell prices.

For instance:

- If you have a standard 20% markup for the FF&E and the freight was 10% of the project's total vendor cost, you can set the overall markup to 30% to cover 20% profit plus 10% freight.

- If the overall freight was 10% of the project's total sell price, you could use the tool to "bump" all prices proportionally to 1.1 times their current value.

- You could add the "sell" freight price as a lump sum to the current project total sell price and then let the tool adjust markups to meet that new total.

The prerequisite is that the project needs to be essentially complete, with the quantities that will be ordered and the sources for products finalized, including whether a product has a separate supplier vendor in addition to the manufacturer vendor. Later changes may change the assumptions used in giving you a freight quote.

Creating the Elements of an "Included" Freight Price

The steps that follow are a "complete" process. You may vary them depending on how you get freight information. Also, if you are familiar with the different ways of adding objects and specifications in FF&EZ, those variations can be used as needed.

- On the Vendor List screen, create a "dummy" vendor ID (e.g., "FRTQUOTE") to which all freight quotes will be assigned. This is to prevent individual freight entries from being accidentally ordered as FF&E items for the vendor providing the quote. More on this later. This only has to be done once.

- If this has not been done, display the Project screen, set the project's freight percentage to zero and apply it to all specifications, per the prompts you will see if you change that value.

- Open the project, then the FF&E Worksheet and run a report that lists the spec costs and their quantities by vendor. There are two than can used for this:

Ordering Worksheet

Projected Profit Detail by Vendor

These reports can be used for reference in getting a quote. The Ordering Worksheet, which does not show sell prices, can be split and sent to vendors or suppliers to get a freight quote.

- On the Area List screen, create an area called "[Other]" or similar. The square brackets cause this area to sort to the bottom of any lists. Then create a room within that area called "[Notes]" or "[Additional]" or something that makes sense for your needs. Both of these names can be changed at any time.

- Display the Objects List screen and create a special object named "[FREIGHT]" and set the object's fields as shown. The two most important ones have arrows. Then click on the [New] button to create a specification for the first freight quote.

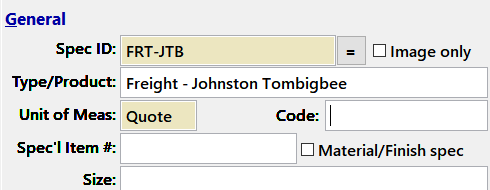

- For the new specification, fill out the fields as shown, based on which vendor is involved (in this example, vendor "JTB"). In the "General" screen section, only these fields are needed. But there are two ways to handle it. One is to record the quote for each vendor as a separate spec and the other is to keep that off system and create a single spec for the total freight:

Option A - Create a freight quote spec for each vendor

This is the method to use if you plan to get a quote from each vendor or supplier. It will create a total freight cost while also recording the exact quotes that were given.

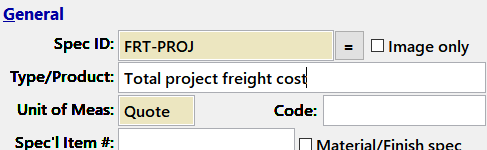

Option B - Create a single freight quote spec for the whole project

Use this method if you want to include the freight in the sell price and either 1) sum the freight quotes off-system or 2) manually calculate a lump sum estimate based on a standard percentage.

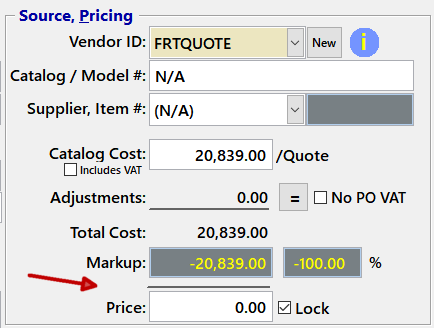

Then, in the "Source, Pricing" section, fill out the fields similar to this:

Note that the price is set to zero. This is important in this approach. If you want to build the freight into the overall price and not bill the customer for a freight line item, this prevents a specific vendor's freight from ever getting into the data.

- Save the specification, which will return you to the Object List. Then save the object to complete the procedure.

- Move to the FF&E Worksheet and use the Add command to add the [FREIGHT] object to the "room" you created in step 4. The quote entry will now appear at the bottom of any reports, including all the quote reports, as the line "Freight and handling is included in the price" but without an associated sell price. The total cost of the freight will appear on the [FREIGHT] object's entry on the Object List screen and will be included in the total project cost on the appropriate reports.

- The sell price of the freight will need to be added to the markup, as described at the beginning of this session. The easiest way to do this described further below.

Adding More Freight Quotes

Once you have the basic pieces created, adding quotes from other vendors is easy.

- Display the Object List screen and highlight the [Freight] object you created in the first section.

- Click on the small Add button below the Component List (at the bottom of the screen).

- Repeat steps 6 and 7 from the previous section to create the specification for the quote.

- If the "Qty/Object" field is blank, be sure to enter a 1, then use the Attach button to add the specification to the components.

- For each freight quote you need to add, use the Add button again to repeat these steps.

Important: The cost represented by the freight "specifications" will be included in all reports comparing cost to sell price. However, the freight estimate object is not converted to orders, since this would create an FF&E line item, not a cost recognized as "freight."

In fact, each order has its own "freight quote" field and each item has fields to record the actual quantity shipped and freight charged by the vendor. These values can vary or be split by phasing, shipping variances, etc. This is why we use a "dummy" vendor for these specifications, since freight is handled differently in the purchasing module.

Adding the Freight to the Project Sell Price

There are three ways to increase the project's sell price to cover the freight costs, all using the Pricing Tool. They can be used whether you are simply passing on the freight cost or are marking it up, so when we refer to "freight" below, we mean whatever total value you intend to charge the customer:

- If you have a flat markup or margin, you can calculate the additional markup percent needed to cover the freight. So if the total freight is X percent of the cost, you would add X percent to the existing markup percent.

If you have varying markups based on certain logical groups, you can use this method in the Pricing Tool to apply an adjusted markup based on the vendor or supplier, a keyword in the short description, the Spec ID prefix and other options.

- Alternatively, you can calculate the freight as a percentage of the existing total sell price and multiply those prices by a factor. So if the total freight is 10% of the total selling price, you can multiply all the prices by 1.1 and have the system calculate the equivalent markups or margins.

- Finally, you can add the total freight quotes to the system's total FF&E sell price and enter that as the project "budget" on the project screen. Then, using the pricing tool's "total price target" option to calculate the proportional markups or margins needed to meet that budget. Note that this method is approximate (depending on other options like price locks) and running it more than once will get you close to the "budget" that you have set.

If you use any of these methods, it is important to ensure that the freight has not been previously added, since all these procedures depend on the base sell price as the starting point.

|