FF&EZ Design/Purchasing Overview

FOR PURCHASING PROJECT CONTENTS

The Purchasing module takes up where the Design module ends, using the FF&E data that has been organized into areas and rooms (or sales quotes) in the Design module and converting it into numbered purchase orders that can be issued, tracked and invoiced.

Since the Design/Purchasing version includes all the features of the Design module, be sure to read about that version to have a complete picture of what Design/Purchasing is about.

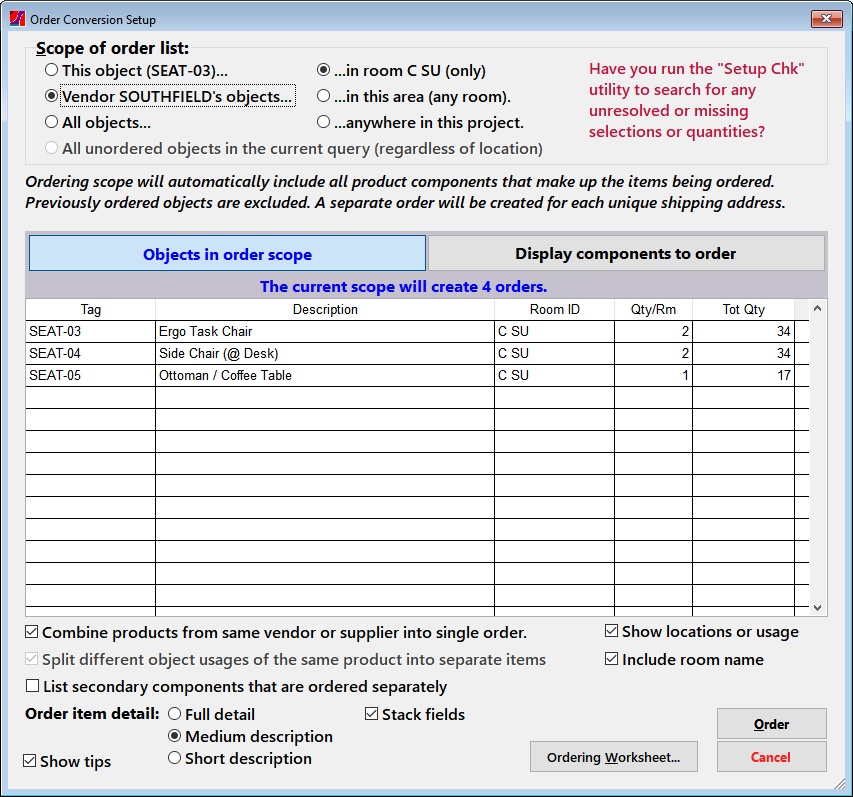

The ordering process starts with the Order command button that appears on the Design module's FF&E Worksheet. Since the FF&E Worksheet shows you the contents of each room in your project, you are working from a natural starting point that you can sort by location, by vendor or by object type. You can also query the data for specific groups of items (such as "order by" dates) as a way of getting a handle on what needs to be ordered. When you click on the Order button, it displays a screen on which you can define a scope of items to convert to orders:

Notice that you can order using a combination of common scopes (groups) of items, or you can order whatever is visible in a query that you have set up prior to clicking on this button. When this pop-up first appears, it displays all the objects in the scope and their locations. Since FF&EZ handles objects that might contain more than one component specification that may be ordered from another vendor, the "Display components to order" button shows the specific products and quantities that will be ordered.

This process creates unissued orders, so the next step is to check the resulting orders and make any final adjustments before issuing them. This is done on the Purchase Orders List screen.

Features

The Purchasing Module includes the following major screens that are used to manage purchase orders:

- Purchase Orders List

- Order Expediting

- Invoices (of either FF&E sales or purchasing fees)

- Check Requests (for payments to vendors)

The Purchase Orders List screen is the heart of the ordering system, providing a single screen from which you can review the majority of information about orders, issue them, revise them, etc.

Centralized processing

On the Orders List and Expediting screens, the Processing function handles issuing orders, check requests and invoices, as well as entry (reconciliation) of vendor invoices for orders. You can process a single order or invoice at a time or process batches of items using standard scopes or query results to speed up throughput.

Flexible data entry and exception handling

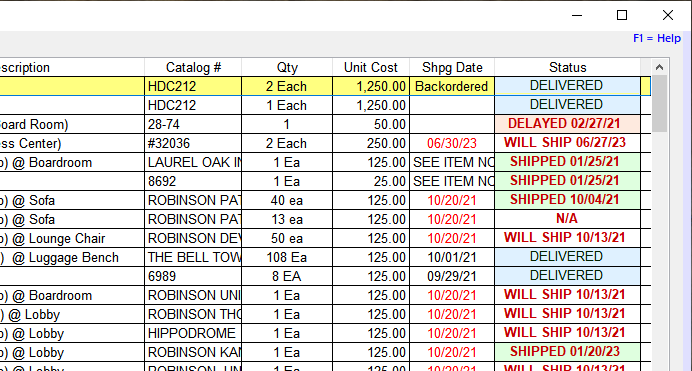

FF&EZ uses the standard division of orders into an order header (containing vendor, client, project and shipping information) and order items, but to this it adds a third level, the item split, which is used to handle the expected (and unexpected) variations in order processing, such as split shipments and split invoices. You can create item splits manually before issuing the order or automatically when shipping quantities or schedules demand it. Each split carries its own set of shipping and delivery status fields.

If your client needs analysis of orders by accounting codes, you can enter these in either the Design or Purchasing modules (codes on the Specification screen carry through to the order items). For an additional cost, a custom plug-in can be designed to do more complex coding if needed.

Data entry tools

FF&EZ users create almost all orders automatically by converting FF&EZ-Design data from the Order command on the FF&E Worksheet, however like FF&EZ-Design the Purchasing system includes functions that allow you to:

- Clone existing orders to create new ones

- Replace existing order items

- Import order items from existing orders, project specs or from the Library

- Route order shipping to another vendor instead of the project or client address

Revision tracking

FF&EZ-Purchasing also includes an automatic revision tracking system that creates user and date-stamped revision notes when you change vendor-related data on issued orders. The revision notes can print automatically when you reprint a PO—with individual items marked by a revision date—and on certain status reports.

Order item status tracking

The Expediting screen and certain reports include a shipping status display that color-codes critical or late items. Expediting functions allow you to update the shipping status of single items or entire orders at one time, with fields to track split shipments or quantity variances (over- or under-runs). Users can make status entries coded to individual items and to some or all items in an order, with an automatic date and user "stamp."

Flexible invoicing

FF&EZ can invoice based on a sell price (in for-profit projects or quotes) or a purchasing fee. On purchasing management projects, it can also issue check requests to your client (or another department) for deposits or payments owed to a vendor. It can easily handle partial invoicing (or check requests) based on the shipping or delivery status of individual order items.

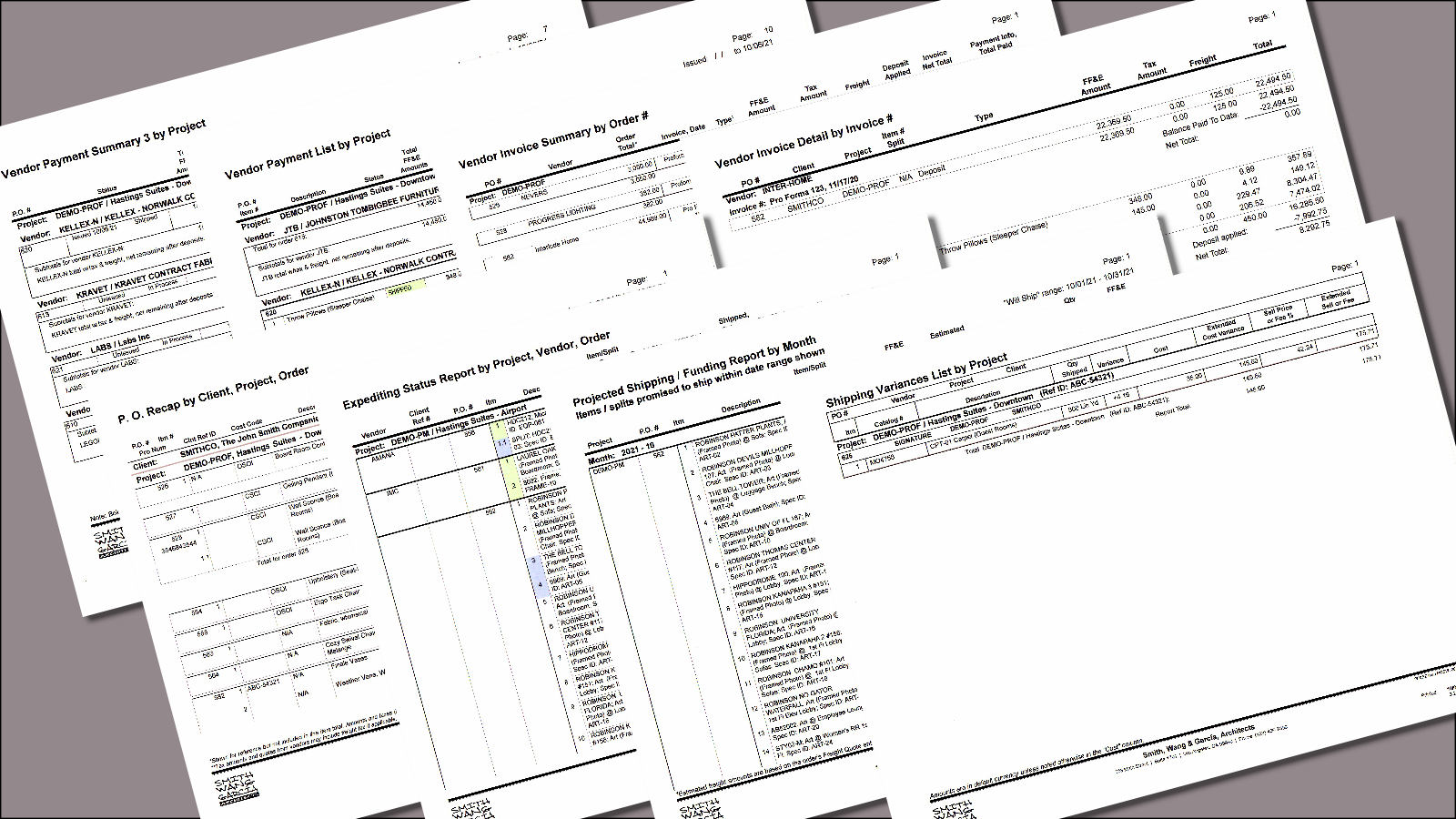

Many useful reports

The system includes dozens of status and analysis reports that can break orders and order items down by vendor, project and/or budget codes (which copy through from FF&EZ-Design).

For pricing and downloadable examples of screens and reports, see the "More Information, Pricing" page.